- DESCRIPTION

-

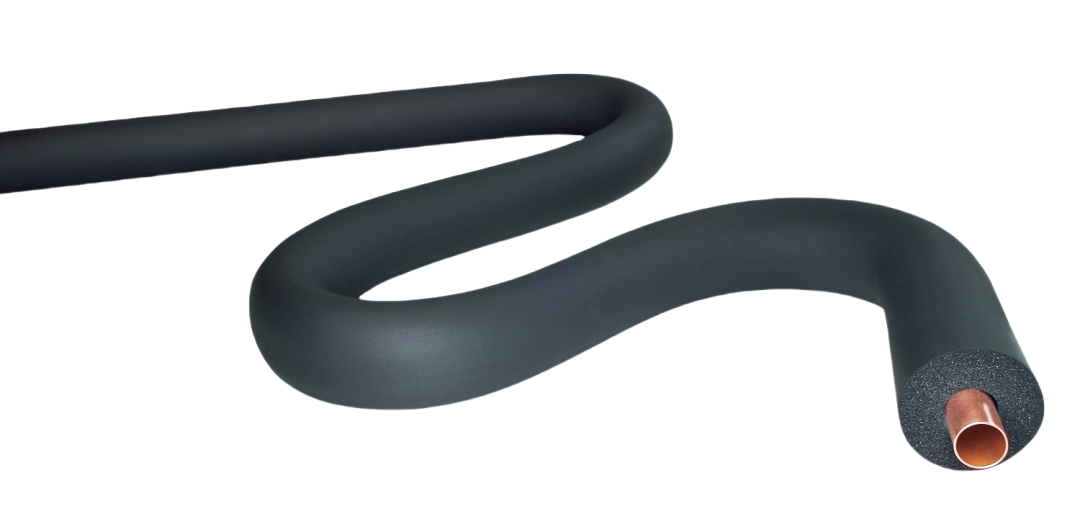

CF-FLEX INSULATION TUBE is an NBR/PVC-based closed cell, flexible elastomeric foam insulation. It is environmentally-friendly as it is free of CFCs, HFCs, HCFCs, PBDEs, formaldehyde and fibers. An EPA-registered antimicrobial agent is incorporated into the product providing additional protection against mold, fungal and bacterial growth.

CF-FLEX INSULATION TUBE is black in color and is available in non-slit, 6’ length tube form in wall thicknesses of 1/4” up to 1-1/2”, in diameter sizes ranging from 3/8” to 4-1/4”. (ID range is subject to variation depending on wall thickness).

Product sizes

THK

ID

1/4”

(PCS/CTN)

3/8”

(PCS/CTN)

1/2”

(PCS/CTN)

3/4”

(PCS/CTN)

1”

(PCS/CTN)

1-1/4”

(PCS/CTN)

1-1/2”

(PCS/CTN)

1/4”

290

168

103

50

33

3/8”

200

132

82

42

30

1/2”

160

108

72

39

26

5/8”

130

90

60

35

24

20

3/4”

108

78

50

32

22

18

7/8”

90

68

48

29

22

16

1”

76

55

42

26

19

15

1-1/8”

66

50

38

24

18

14

1-1/4”

56

44

36

20

16

13

1-3/8”

48

40

30

20

16

12

1-1/2’

35

27

18

15

11

1-5/8’

35

24

18

14

11

1-7/8”

32

20

14

12

10

2”

30

20

12

12

2-1/8”

28

20

12

12

2-3/8”

28

17

10

10

8

3”

17

10

8

6

5

3-1/2”

14

10

8

6

5

4-1/4”

6

6

4

Product Parameters

PROPERTY TEST METHOD VALUE Density GB/T 6343 40-65 kg/m3 (2.5-4 lbs/cu-ft) Thermal conductivity GB/T 10294 0.031 w/m*k @-20℃ 0.034 w/m*k @ 0℃ 0.036 w/m*k @+20℃ Water vapor permeability GB/T 17146 1.6 x 10-11 g/(m-s-pa) Moisture resistance factor GB/T 17146 12,000 Water absorption ration in vacuum GB/T 17794 < 2% Fire Propagation BS 476-6, BS476-7 Class 0, Class 1 Combustibility grade GB/T 8624 B1 Oxygen index GB/T 5454 35 SDR GB/T 8627 56 Dimension stability, 105±3℃, 7d GB/T 8811 7% Crack resistance GB/T 10808 2.76 N/cm Ozone Resistance, 202Mpa 200h GB/T 7762 No cracking Odor Emissions ASTM C1304 No objectionable odor Chemical/Solvent/Oil/Grease Resistance Good Flexibility ASTM D1056 Excellent Mildew Growth Resistance/Air Erosion UL 181, ASTM G21 Pass Aging resistance GB/T 16259 No cracks, no pin holes, not deforming Sound Transmission Class (1”) ASTM E90 13 Service temperature GB/T 17794 -40-110 °C (-40-230 °F) BS476 PART 6 & 7, CLASS 0 & 1, Fire Propagation: Sub index ≤ 6, Total index ≤ 12

GB 8624-2012, B1 (C-s3, d0, t1) , Oxygen index > 32, SDR: 56

It is acceptable for duct/plenum applications. Numerical flammability ratings alone may not define the performance of products under actual fire conditions. They are provided only for use in the selection of products to meet limits specified when compared to a known standard.

Product Application

- Chilled water pipe insulation

- Air conditioning insulation

- Copper pipes insulation

- Hot water pipe insulation

- Solar system insulation

- Auto system insulation

Packaging

By carton boxes

Carton dimensions: 1870x385x326 mm, 305 cartons/40' HQ, used for pipes of 1.83 meters length

Carton dimensions: 2070x385x326 mm, 272 cartons/40' HQ, used for pipes of 2.00 meters length.

Previous: none

You May Also Like

Leave a Message

We will contact you as soon as possible